Preventive Maintenance For Long Valve Life

- Posted by:

- Admin

- Tags:

- valves, maintenance, safety, isolation, lockout, tagout, venting, tools, spares, torque, spanners, gauges, callipers, sealant, antiseize, grease, lubrication, gearbox, bearings, stems, glands, packing, seals, seats, gaskets, leaks, inspection, corrosion, rust, coatings, cleaning, testing, pressure, temperature, records, actuators, fasteners

- Posted date:

Before touching any valve, isolate the line and confirm it is at zero energy. Lock out and tag out the source so no one can open a feeder or start a pump by mistake. Vent or drain the trapped pressure, and test the body with a small crack at a bleed point to ensure it is safe. Treat every valve as pressurised until you prove otherwise with the right checks. Always wear the correct PPE (personal protective equipment) for the specific fluid and the...

Posted by: Admin on: Read More

Common Valve Failures And How To Prevent Them

- Posted by:

- Admin

- Tags:

- valves, leakage, gaskets, torque, packing, seats, seals, stems, sticking, seized, corrosion, chloride, pitting, porosity, offshore, salt, maintenance, inspection, lubrication, alignment, overheating, thermal, shock, cavitation, flashing, erosion, wear, materials, stainless, duplex, elastomers, graphite, ptfe, filtration, strainers, actuator, vibration, noise, reliability, safety

- Posted date:

Leaks often start at joints, flanges, and threaded connections, where small gaps can develop. Vibrations, poor gasket selections, or uneven bolt loads allow fluids to find a route out. As time passes, thermal cycles tend to loosen the fasteners and crush gaskets, which widens the path. A leak that starts as a mist can grow into a steady loss if it is not immediately addressed. Prevention begins with sound joint design and assembly practice. Make...

Posted by: Admin on: Read More

The Role of Structural Steel in Modern Construction

- Posted by:

- Admin

- Tags:

- innovation, steel, construction, sustainability, recycling, technology, design, architecture, engineering, materials, future, strength, durability, efficiency

- Posted date:

Discover the role of structural steel in modern construction. Learn how it supports tall buildings, bridges, and infrastructure with strength and speed. Structural steel plays a major role in the overall construction of high-rise buildings. Its high strength-to-weight ratio allows building developers to design tall, slender structures that have the ability to support lots of heavy loads without adding any unnecessary bulk. This makes steel...

Posted by: Admin on: Read More

Structural Steel vs Other Building Materials

- Posted by:

- Admin

- Tags:

- construction, steel, concrete, timber, aluminium, masonry, buildings, materials, durability, strength, cost, safety, fire, design, structures

- Posted date:

Explore the advantages of Structural Steel vs Other Building Materials for durability, cost-efficiency, and speed. Make informed choices for your construction project. When planning a construction project, it is useful to compare structural steel with other building materials. Several alternatives are often chosen depending on cost, design goals, and environmental factors. Below are some of the most common options. Concrete is one...

Posted by: Admin on: Read More

Hydrostatic Testing for Firefighting Equipment

- Posted by:

- Admin

- Tags:

- hydrostatic testing,firefighting equipment,health and safety regulations,hydrotesting guide

- Posted date:

Find out more about hydrostatic testing for firefighting equipment. Hydrostatic testing ensures your gear’s safety, durability, and compliance. Firefighting equipment must work flawlessly the first time, every time. Hydrostatic testing verifies the integrity of hoses, nozzles, hydrants, portable fire extinguishers, and breathing-air (SCBA) cylinders. By proving that these components can safely withstand high amounts of pressure,...

Posted by: Admin on: Read More

How Hydrostatic Testing Protects Water Supply Systems

- Posted by:

- Admin

- Tags:

- hydrostatic testing,water contamination,water testing and prevention,hydrostatic testing guide

- Posted date:

Discover how hydrostatic testing protects water supply systems by detecting leaks and ensuring they are structurally sound, safe and compliant. Hydrostatic testing is essential for verifying the strength and integrity of water supply systems. Hydrostatic testing works by filling pipes or tanks with water and pressurising them beyond their normal operating levels to detect leaks and structural weaknesses before the system goes into service. Hydrostatic...

Posted by: Admin on: Read More

Common Industries That Use Bespoke Fabrication

- Posted by:

- Admin

- Tags:

- energy, utilities, power, gas, water, renewables, fabrication, infrastructure, safety, equipment, maintenance, systems, platforms, enclosures, supports, installation, durability, access, housing, brackets

- Posted date:

Explore how industries that use bespoke fabrication benefit from tailored manufacturing, improving durability, safety, and performance for construction, public sector, and more. Construction, manufacturing, and building tend to be the most common industries relying on bespoke fabrication to carry out work. These essential sectors often need brand-new parts and structures to match the exact sizes, shapes, and functions of your project. When...

Posted by: Admin on: Read More

The Main Uses of Custom Fabrication in Construction

- Posted by:

- Admin

- Tags:

- construction, fabrication, custom, components, materials, design, architecture, equipment, safety, efficiency, site, machinery, building, structure, finishes, benefits, accuracy, modification, features, installation

- Posted date:

We explore the main Uses of custom fabrication in construction. Custom fabrication ensures precise parts, enhance safety, and optimise project efficiency. Discover how customised components benefit your build. Custom fabrication is the concept of designing and producing materials or components that meet the specific needs of a project. This usually involves cutting, shaping, or assembling materials, for example, metal, plastic, or wood,...

Posted by: Admin on: Read More

Items That Require Hydrostatic Testing

- Posted by:

- Admin

- Tags:

- Hydrostatic Testing,Pipelines,Fire Extinguishers,Pressure Vessels,Heating Systems

- Posted date:

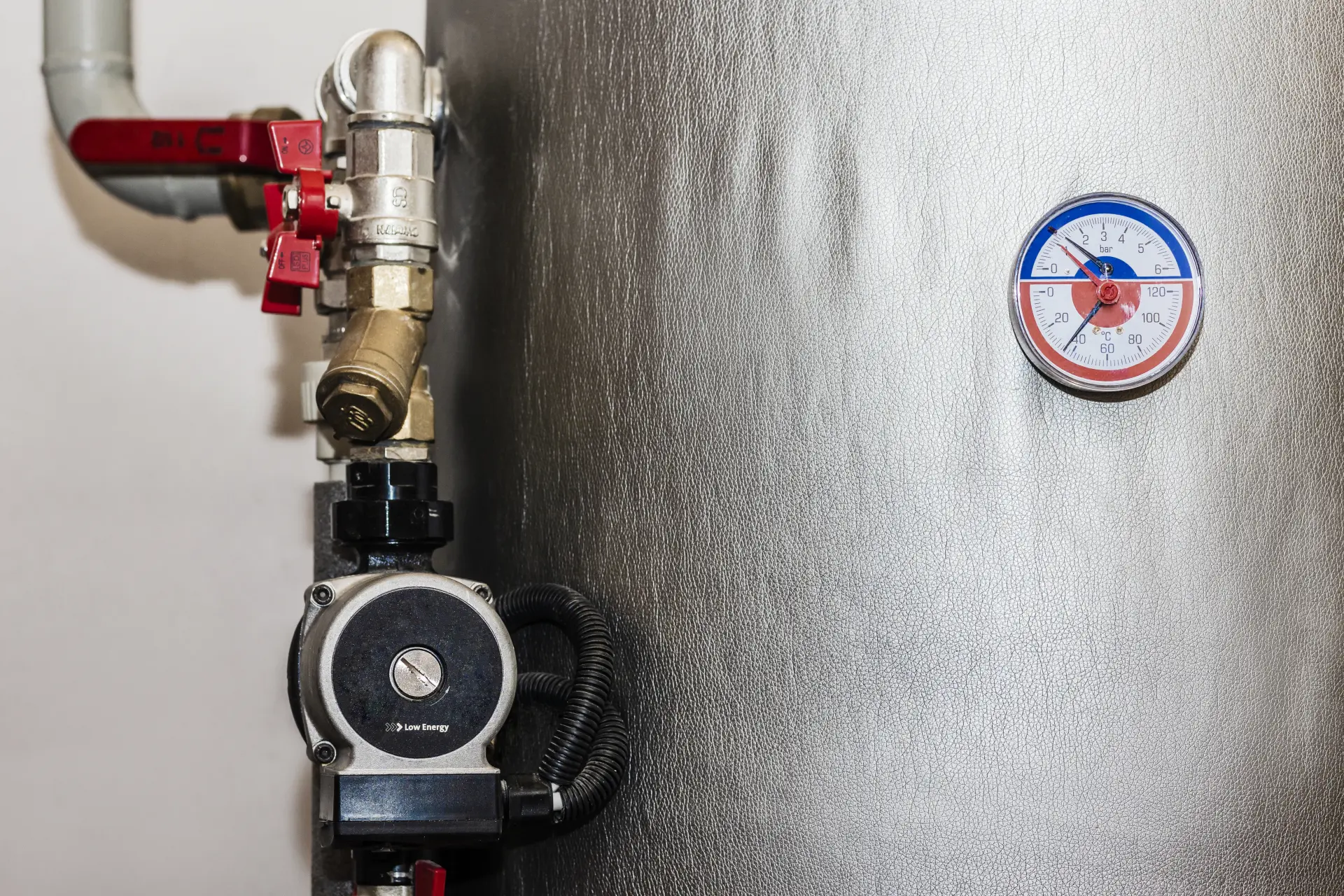

Hydrostatic testing is a safety process used to check the strength and leak-tightness of many types of equipment. It uses water to test for leaks or weak points. The pressure applied during the process helps reveal any damage or flaws in the item being tested. Discover common items that require hydrostatic testing, including pipelines, boilers, and pressure vessels. Learn why this process is essential for safety and leak prevention. Pipelines...

Posted by: Admin on: Read More

When Do You Need Hydrostatic Testing

- Posted by:

- Admin

- Tags:

- Hydrostatic Testing,Safety Checks,Repairs,Leaks,Damage

- Posted date:

Hydrostatic testing is a method used to check if a system can handle pressure safely. It uses water to find leaks and weaknesses. This process may be required for safety, legal, or maintenance reasons. Find out when do you need hydrostatic testing, including after repairs, during safety checks, or before using old equipment. Learn how this process helps detect leaks and keeps systems safe. New equipment like pipes, tanks, or...

Posted by: Admin on: Read More

The Main Types of Structural Steel and Their Uses

- Posted by:

- Admin

- Tags:

- Structural Steel,Steel Types,Steel Uses,Strength,Construction

- Posted date:

Structural steel is a strong, reliable material used in a wide range of construction projects. Different types of steel offer different benefits, including resistance to corrosion, shape flexibility, and high strength. Here's a breakdown of the most commonly used structural steels and where they're best applied. This article looks at the main types of structural steel and their uses. Mild steel is one of the most...

Posted by: Admin on: Read More

Key Properties of Structural Steel

- Posted by:

- Admin

- Tags:

- Structural Steel,Strength,Durability,Recyclability,Ductility

- Posted date:

Explore the key properties of structural steel, including strength, ductility, toughness, and weldability. Structural steel is a popular choice in construction due to its strength, durability, and versatility. Made primarily from iron and carbon, it can be shaped and formed to meet the needs of many types of structures. What sets structural steel apart is its combination of physical and chemical properties that offer reliability...

Posted by: Admin on: Read More

Why Structural Steel Is Popular in Commercial Buildings

- Posted by:

- Admin

- Tags:

- Structural Steel,Commercial Buildings,Design,Cost,Large Buildings

- Posted date:

Structural steel is widely used in commercial construction across the UK. Its unique mix of strength, flexibility, and reliability makes it a key material in modern building projects. Whether for office towers, warehouses or retail centres, steel continues to meet the growing need for durable, cost-effective solutions in commercial developments. Builders and developers are turning to steel for faster builds, long-term savings, and design...

Posted by: Admin on: Read More

The Benefits of Coded Welding for Industrial Pipework

- Posted by:

- Admin

- Tags:

- coded pipe welding,safety standards,risk reduction,pipe welding codes and standards

- Posted date:

Reduce costs and boost efficiency with coded welding for industrial pipework. Invest in defect-free, strong joints that withstand demanding conditions. Coded pipe welding ensures that industrial pipework is constructed to the highest standards regarding strength and durability. Coded welders follow strict procedures set by ASME and BS EN to create high-quality welds that can withstand temperature fluctuations, extreme pressures and mechanical...

Posted by: Admin on: Read More

Understanding Welding Codes and Standards for Pipe Welding

- Posted by:

- Admin

- Tags:

- coded pipe welding,standards and regulations,welding codes,health and safety in welding

- Posted date:

Find out more about 'Welding Codes and Standards for Pipe Welding' keep your industry safe by ensuring durable, defect-free, and fit-for-purpose welded structures. Welding codes and standards provide guidelines on welding techniques, materials and testing procedures to ensure that welded structures are strong, durable, and fit for purpose. Many industries deal with high-pressure systems, flammable gases, and extreme temperatures, where...

Posted by: Admin on: Read More

Which Industries Require Coded Pipe Welders

- Posted by:

- Admin

- Tags:

- pipe welding,coded pipe welding,pipelines,welding

- Posted date:

Discover how many industries require coded pipe welders! Our services span water & waste plants, shipbuilding, petrochemicals & power generation. The water and waste treatment industry relies heavily on coded pipe welders to ensure the efficiency of its infrastructure. These facilities use a network of pipes to transport chemicals, water and waste materials, making high-quality welding essential to prevent leaks, contamination,...

Posted by: Admin on: Read More

Common Industries That Rely on Hydrostatic Testing

- Posted by:

- Admin

- Tags:

- safety regulations,hydrostatic testing,pipes and pressure vessels,equipment testing

- Posted date:

Learn about the Common Industries That Rely on Hydrostatic Testing for equipment safety, and reliability from Oil & Gas to Manufacturing. The oil and gas industry heavily relies on hydrostatic testing to ensure the safety, reliability, and efficiency of its infrastructure. Pipelines in this sector transport volatile and valuable materials under high pressure across extensive distances. Leaks or ruptures in these systems can...

Posted by: Admin on: Read More

How Hydrostatic Testing Ensures Equipment Safety

- Posted by:

- Admin

- Tags:

- hydrostatic testing,hydrostatic equipment,safety checks,health and safety

- Posted date:

How does Hydrostatic Testing help ensure equipment safety? Uncover its importance, particularly for high-pressure systems, to reduce safety risks and improve reliability. Hydrostatic testing assesses the integrity and safety of equipment that operates under pressure. This testing method involves filling the equipment with water or another incompressible fluid and applying pressure to ensure it can withstand its operating conditions without...

Posted by: Admin on: Read More

What Is Hydrostatic Testing and Why Is It Important

- Posted by:

- Admin

- Tags:

- hydrostatic testing,advice,pressure testing,safe pressure testing

- Posted date:

Are you curious about hydrostatic testing and why is it important? Learn how this essential service detects leaks and ensures safety by testing your systems under pressure. Hydrostatic testing is used to check pipelines, pressure vessels and other systems that hold liquids or gases under pressure for leaks or structural faults. The process involves filling the system with water or another non-compressible liquid that's typically dyed...

Posted by: Admin on: Read More

The Impact of Poor Pipe Fitting on Industrial Operations

- Posted by:

- Admin

- Tags:

- pipe fitting,pipe systems,pipe installation,pipe repair,pipe risks

- Posted date:

Discover the impact of poor pipe fitting on industrial operations. Explore causes, consequences, and best practices to prevent inefficiencies and risks. Poor pipe fitting in industrial operations often has several key causes. One major issue is the lack of skilled labour. When workers are not adequately trained, improper pipe installation and connections occur. Substandard materials can cause pipe fitting problems. Low-quality...

Posted by: Admin on: Read More

When Do I Need To Hire A Mobile Welder

- Posted by:

- Admin

- Tags:

- Mobile Welding,Gates,Fencing,Costs,Remote

- Posted date:

Mobile welding offers expert on-site metalwork, perfect for large, immovable projects or urgent repairs. This article highlights when to hire a mobile welder and the key benefits of this convenient service. Mobile welding is the process of welding metals on-site using portable welding equipment. Unlike traditional welding services that require you to transport your materials to a workshop, mobile welding services come to your location...

Posted by: Admin on: Read More

What Does It Mean to Be a Coded Welder

- Posted by:

- Admin

- Tags:

- Certified Welders,Coded Welders,Welding Certifications,Welding Joints,Welding Codes

- Posted date:

A coded welder is a welder who has passed a welder approval test to prove they can weld to a particular specification. In simple terms, it means they have shown, through testing, that they can make high quality welds that meet welding codes and industry standards. This matters because coded welds are often used in safety critical applications where a failure could cause serious harm. C Coded welders usually work in areas like construction,...

Posted by: Admin on: Read More