We explore the main Uses of custom fabrication in construction. Custom fabrication ensures precise parts, enhance safety, and optimise project efficiency. Discover how customised components benefit your build.

What is Custom Fabrication?

Custom fabrication is the concept of designing and producing materials or components that meet the specific needs of a project. This usually involves cutting, shaping, or assembling materials, for example, metal, plastic, or wood, as these best match detailed measurements or design plans.

Unlike standard, ready-made products, custom-fabricated items are created from scratch depending on the project requirements. This typically involves items like brackets, support beams, railings, or ductworks for construction. Custom fabrication makes sure that every part fits correctly, works properly, and supports the overall strength, safety, and design of a building or structure.

Architectural Features and Finishes

Custom fabrication plays a significant role in creating distinctive architectural features in construction. These can include a broad range of useful structural elements such as staircases, balustrades, cladding, columns, and canopies.

Each of these features can be reshaped and sized to suit the exact layout and design of a building. This level of detail allows many architects and builders to add character, style, and function to both the interior and exterior of a structure.

Finishes are just as vital as the features themselves. With custom fabrication, materials can be treated or coated to achieve a wide range of looks—such as polished, brushed, matte, or textured surfaces.

This helps match the building’s overall style, whether modern, industrial, or traditional. Your structures will also experience plenty of practical benefits, such as increased durability, easier cleaning, and improved weather resistance.

Site-Specific Components

Site-specific components are specially designed parts that fit the exact requirements of a particular construction site. Every site is different. For example, some may have uneven ground, tight spaces, unusual layouts, or existing structures that need to be worked around.

Standard materials usually won’t fit these unique conditions for a number of reasons, but this is where custom fabrication becomes a part of construction. Builders can use this to create components like angled supports, fixing brackets, structural joints, or frames that match the site’s exact measurements and conditions.

With the help of site-specific components, you can improve both the accuracy and efficiency of construction. It is also useful for reducing the need for on-site adjustments, which lowers the risk of errors and speeds up installation.

It can also create a much safer working environment for all your employees, as all parts are made to fit securely and perform their function correctly. Overall, custom-fabricated site-specific components help make complex building projects more manageable and reliable.

Equipment and Plant Modifications

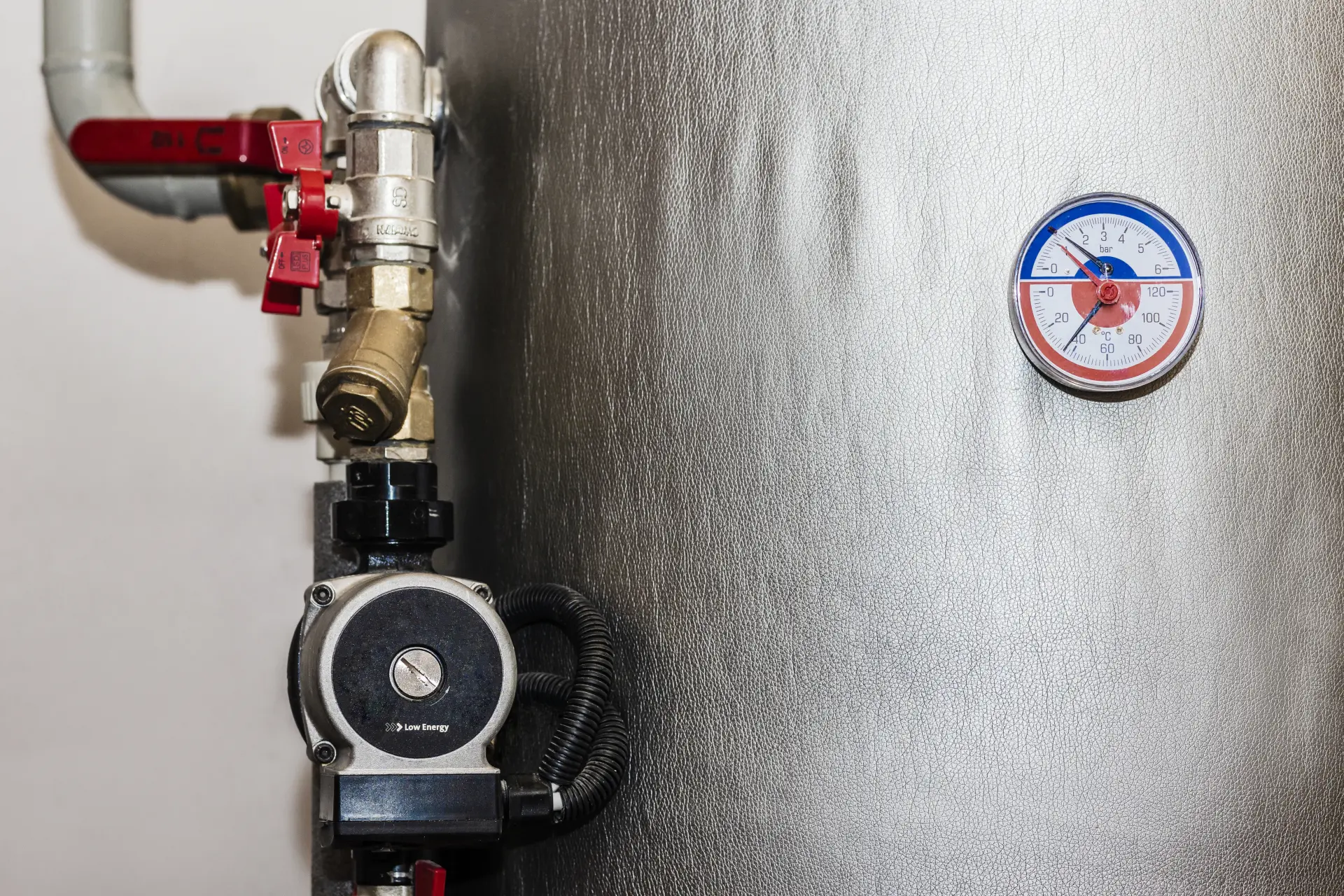

This type of fabrication is widely used throughout the construction industry to adapt construction equipment and plant machinery for specific tasks or site conditions. Standard machines are often built for general use, but many projects require tools that perform a unique function or operate in restricted spaces.

Fabrication also involves the adjustment of parts such as machine guards, access platforms, lifting attachments, or protective housings. These changes can improve the function of your equipment, helping it to fit the job more precisely.

Modifying equipment through fabrication also brings important safety and efficiency benefits.

Custom parts can reduce the risk of accidents by providing better protection for workers and clearer access to controls.

They can also improve the performance of machinery, making tasks quicker and more accurate.

This helps keep your building projects on schedule and makes sure that all equipment is being used to its full potential.

Benefits of Using Custom Fabrication in Construction

Custom fabrication offers many benefits for any kind of construction work by allowing materials and components to be made to exact specifications. This leads to better accuracy, which means parts fit properly and perform as expected, reducing delays and mistakes on site. If you're looking for more creative and flexible designs, this method can help your buildings meet both functional and visual goals.

It can improve the overall safety by producing multiple parts that meet strict health and safety standards and work well in specific conditions. It is a great way to reduce waste, as materials are cut and used more efficiently. Overall, using custom fabrication helps make construction projects easier, more reliable, cost-effective, and high in quality.

If you're searching for a trustworthy company to assist with fabrication and engineering in Manchester, Stockport, Salford and Wilmslow, give our team a call today. We'll do all we can to meet your needs for safe and functional construction work.