Hydrostatic testing is a method used to check if a system can handle pressure safely. It uses water to find leaks and weaknesses. This process may be required for safety, legal, or maintenance reasons.

Find out when do you need hydrostatic testing, including after repairs, during safety checks, or before using old equipment. Learn how this process helps detect leaks and keeps systems safe.

After New Equipment Is Installed

New equipment like pipes, tanks, or cylinders must be tested before they go into service. Even if they are brand new, small faults or damage from transport can cause a leak once the system is under pressure.

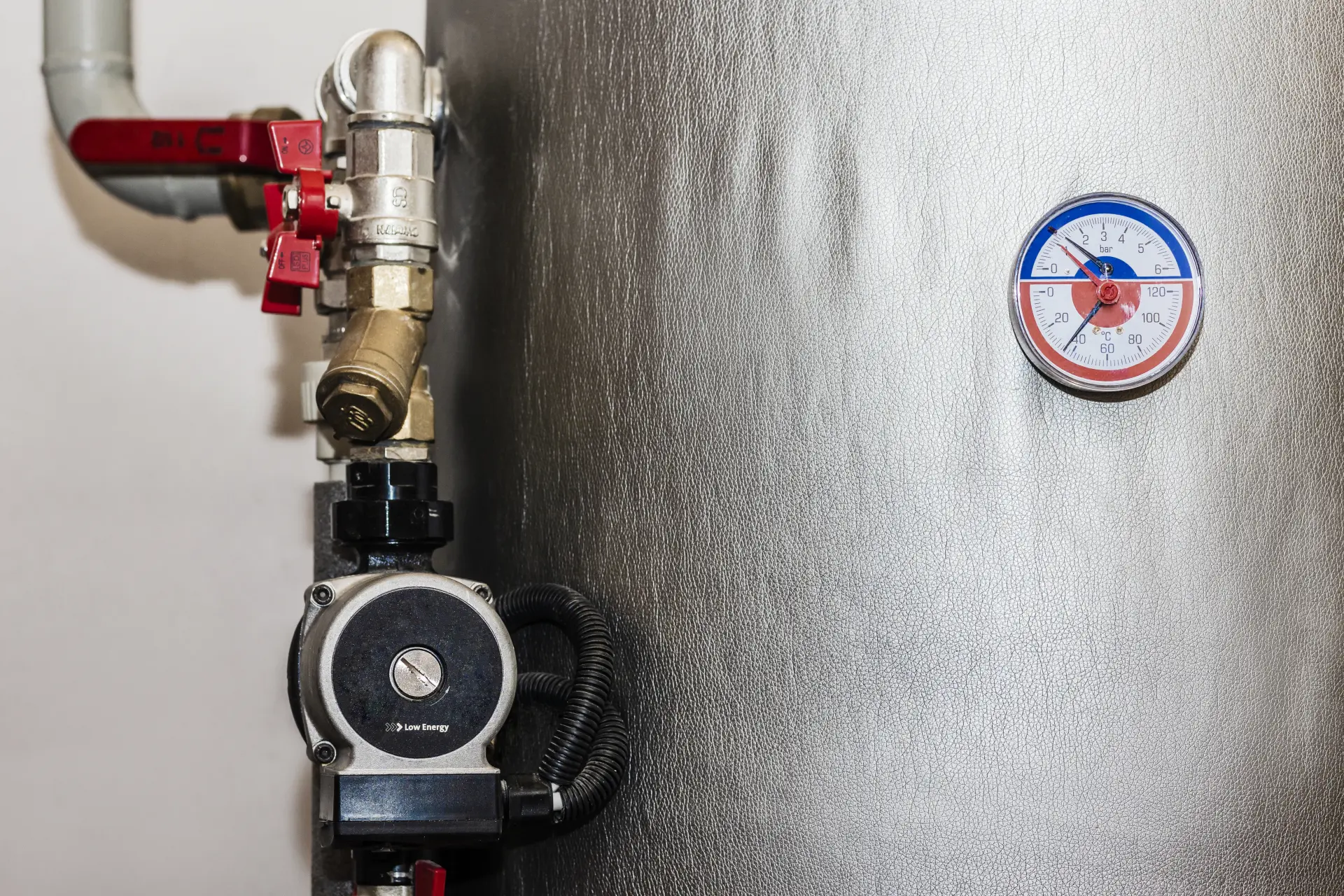

A hydrostatic test helps spot these problems early. Water is used to pressurise the system. If any leaks appear, repairs can be made before the system is fully used. This step is often required as part of the installation process. It helps confirm that the equipment is safe to operate and meets the needed standards for pressure and reliability.

The test also helps the company providing the equipment prove that it is fit for purpose. Many businesses that supply high-pressure systems include hydrostatic testing as part of their standard services.

During Routine Safety Checks

Systems that carry water, gas, or other fluids under high pressure should be checked regularly. These routine checks help make sure everything is still safe and working properly.

Hydrostatic testing is one of the best ways to do this. It helps find leaks that may not be visible but could cause damage or danger if left untreated. Over time, wear and tear can affect joints, seals, and other parts of the system. The test provides clear results and helps identify where repairs may be needed.

A company that offers testing services can carry out these checks and provide proof that the system has passed. This information may be needed for health and safety records or legal inspections.

After Repairs or Modifications

If a system has been repaired or changed in any way, it will likely need to be tested again. A repair may fix one problem but cause another if not done carefully.

A hydrostatic test is used to make sure the whole system is still safe. This process helps confirm that the repaired area does not leak and that the system can still handle the same level of pressure as before. Even small changes to pipes or fittings can affect the way a system works under pressure.

Testing after repairs is a key part of maintaining trust in the system. It helps ensure that the equipment continues to meet the standards required for its use.

If There Are Signs of Leaks or Damage

Any sign of damage should be taken seriously. This includes drops in pressure, visible leaks, or changes in how the system works. These signs may mean there is a hidden problem.

Hydrostatic testing uses water to apply pressure and check for leaks. If a leak is found, the system can be fixed before it fails. This kind of test helps stop small problems from turning into big ones. Leaks in high-pressure systems can lead to serious accidents or system shutdowns.

Regular testing when faults are suspected helps limit risk and ensures ongoing safety in the workplace or home.

On Equipment That Has Been Unused for a While

If a tank, boiler, or line has not been used for months or years, it may no longer be safe. Rust, corrosion, or age can weaken the system without anyone knowing.

Before using the equipment again, a hydrostatic test may be required. This test helps ensure that the system is still strong enough to do the job. Many companies offer these services as part of pressure system maintenance. Water is used to apply pressure and test the strength of the container or pipe.

Using equipment that has not been tested after a long break can be risky. Hydrostatic testing helps reduce that risk and gives peace of mind.

Hydrostatic testing ensures the safety, reliability, and compliance of systems by detecting issues and protecting the environment across various industries. Anderson Engineering And Welding Services provides expert hydrostatic testing in Manchester & the North West that are guaranteed to keep your equipment in good condition.