Coded Pipe Welding Services Near Me

Anderson Engineering And Welding Services is available to assist with all your welding and fabrication needs. We offer high quality coded pipe welding services throughout Manchester and UK-wide.

We are quick, precise and stick to the agreed project timelines. For any welding needs, choose Anderson Engineering And Welding Services, your new go-to partner.

On-Site Pipe Welding Solutions

At Anderson Engineering And Welding Services, we offer excellent on-site pipe welding solutions. Our skilled team is available to tackle any welding challenge you may face. Trust Anderson Engineering And Welding Services for reliable, top-quality welding solutions.

Custom-Coded Pipe Welding

Our team at Anderson Engineering And Welding Services offer a hand in custom-coded pipe welding projects. We deliver high-quality results according to our clients' detailed specifications.

We adhere strictly to quality standards, guaranteeing professional outcomes that meet the unique needs of our customers.

Repair & Maintenance Welding

Anderson Engineering And Welding Services offer a range of welding repair and maintenance services. Our aim is to extend the lifespan of your structures, ensuring they remain durable.

Trust us for reliable, high-quality services that consistently meet and exceed industry standards.

Fabrication & Assembly

At Anderson Engineering And Welding Services, we specialise in providing fabrication and assembly services.

Our services cater to a range of industries. Whether it's automotive, aerospace, construction, or medical industry, we are equipped to deliver high-quality solutions.

Welding Procedure Specification

We always maintain high standards of quality and consistency. We achieve this by following stringent Welding Procedure Specifications.

This method allows us to deliver industry-leading results, ensuring all welding tasks are executed with precision.

Project Management

We specialise in managing large-scale projects. Our project management team mitigates potential complications.

Our approach means risks are managed effectively, contributing to the project's success.

Coded Pipe Welding Services in Manchester

At Anderson Engineering And Welding Services, we provide coded pipe welding services throughout Manchester and the North West. We ensure high quality and safety in all our projects. We have a highly skilled team that work tirelessly to guarantee our pipe welding jobs stand the test of time.

Efficient Solutions

We offer a range of services specially designed to meet our clients' diverse needs across various sectors, including domestic, commercial and industrial.

Our expertise, dedication and innovative solutions make us a trustworthy partner to support you in achieving your project goals.

Varying Materials

Anderson Engineering And Welding Services work with a variety of pipe materials and sizes. This flexibility enables us to easily accommodate your unique project requirements.

Regardless of the complexity, we aim to provide tailor-made solutions that align perfectly with your needs.

Strict Compliance

Our strict adherence to both ASME and BSEN standards stands as a testament to our commitment towards delivering high quality services.

Anderson Engineering And Welding Services always ensures compliance with these benchmarks to uphold industry excellence.

Our Welding Services

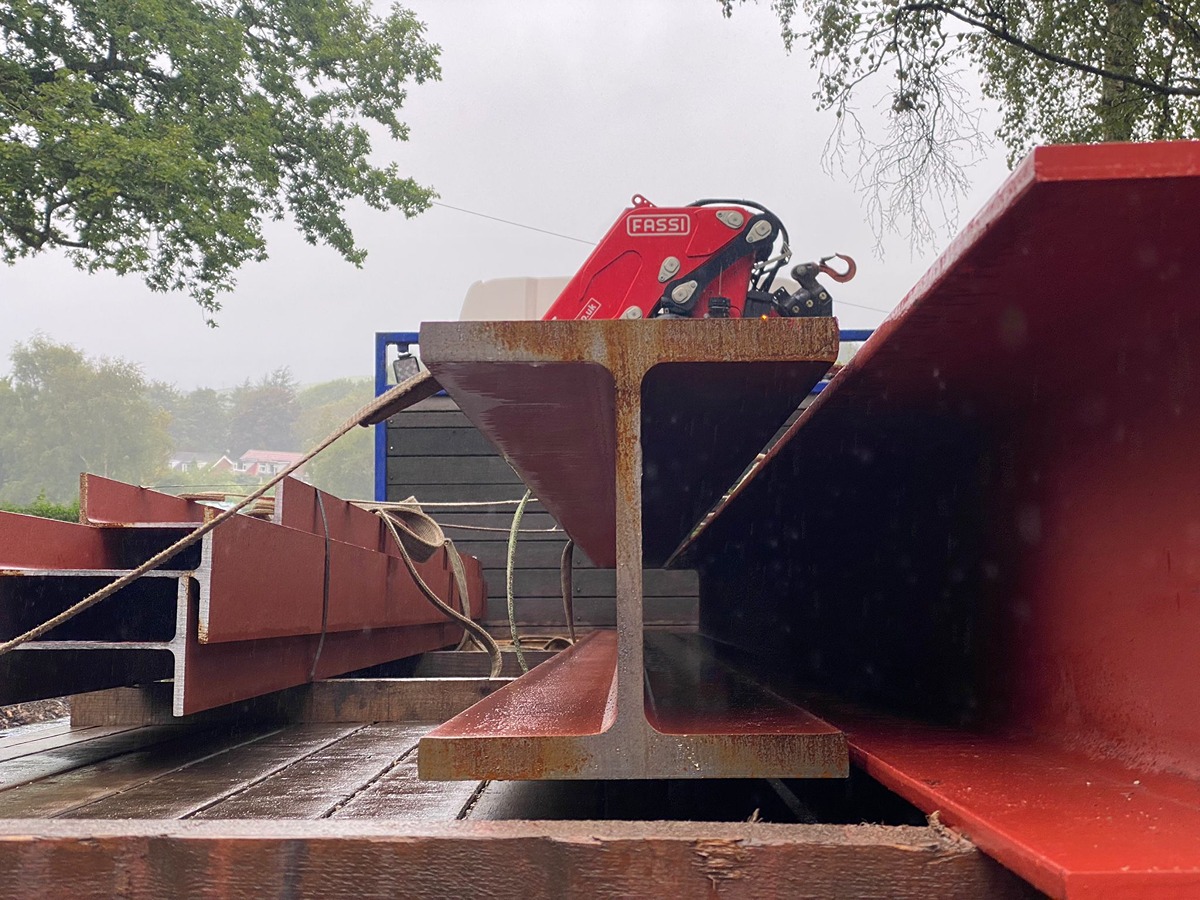

Structural Steel Suppliers Manchester

Are you looking for structural steel supply and installation services? Your search ends here with Anderson Engineering And Welding Services. We offer top-tier engineering services, ensuring your projects are completed with utmost precision and quality.

Mobile Welding Services Manchester

At Anderson Engineering And Welding Services, our engineers provide a high-quality mobile welding service. They guarantee flawless work on each project, ensuring that your expectations are always met, if not exceeded, every single time.

Bespoke Fabrication Services Manchester

With Anderson Engineering And Welding Services, you can transform your ideas into reality. Our customised fabrication services are tailored to meet your unique requirements with precision and finesse.

Frequently asked questions about Coded Pipe Welding

Coded pipe welding is a specialist form of welding where the welder has passed specific tests to recognised standards such as ASME or BSEN. It ensures every weld meets strict safety and quality requirements.

This type of certification proves the welder is competent in a particular material, welding position, and process, making it essential for high-pressure or critical applications.

Coded welding is important because it guarantees the welds meet industry-approved specifications. This helps protect people, property, and equipment from risks caused by poor workmanship.

It is particularly critical in industries like oil, gas, and construction, where even small welding faults could lead to expensive or dangerous failures.

A ‘coded’ welder is someone who has successfully completed tests under a welding standard and is certified to carry out that procedure. Their ability has been proven through examination and inspection.

Once certified, the welder is authorised to perform that type of welding for projects requiring guaranteed safety and reliability.

Coded welding covers a wide range of materials such as carbon steel, stainless steel, aluminium, and specialist alloys. Each welder’s certification specifies which materials they are qualified to work with.

This flexibility means coded welding can be applied across many sectors that require durable, high-quality joins in demanding environments.

Coded pipe welding is widely used in industries where strength and safety are critical. These include oil and gas, power generation, petrochemical, water treatment, aerospace, and construction.

Each of these industries relies on coded welders to ensure that every joint can withstand pressure, stress, and long-term use without failure.

Common standards for coded welding include ASME IX, BS EN ISO 9606, and AWS. These certifications define the materials, processes, and welding positions a welder is qualified for.

By working to these standards, welders and companies can demonstrate their compliance with international safety and quality requirements.

Coded welding is tested using methods like ultrasonic inspection, x-ray checks, bend tests, and hydrostatic pressure testing. These confirm that the weld is strong and free of defects.

By passing these checks, coded welds are proven safe for use in high-pressure systems and other demanding applications.

The main benefit is assurance of quality and compliance with recognised safety standards. A coded welder’s work reduces risks and avoids costly rework or system failures later on.

For clients, this provides peace of mind that all welding tasks will be delivered to the highest possible standard.

Yes, coded welding can be performed both on-site and in a controlled workshop setting. Mobile coded welders bring the required expertise directly to your project location.

Workshops, on the other hand, provide stable conditions for precision welding when projects benefit from off-site fabrication.

Yes, Anderson Engineering And Welding Services provides certified coded pipe welding services across Manchester, Stockport, and the wider North West. Our team are fully trained to ASME and BSEN standards.

We have the expertise and equipment to deliver dependable, high-quality welding solutions for industrial and commercial projects of all sizes.