Industrial Pipe Fitting Near Me

Are you looking for high-quality industrial pipe fitting services near you? Look no further! Based in Stockport, Greater Manchester, Anderson Engineering And Welding Services deliver a range of high-quality pipe fitting services.

Our specialists provide custom solutions to meet your specific industrial pipe fitting requirements. Our aim is to deliver quality and precision in every project.

Our Range of Industrial Pipe Services

At Anderson Engineering And Welding Services, we provide a range of industrial pipe services, designed to cater to a variety of needs. Our services include not only the installation of industrial pipes but also bespoke pipe fabrication.

We understand that there are times when you'll require on-site repairs and hence, we provide this service for instances when pipe joining and welding are needed. In addition, we've established a facility specifically for valve refurbishment. Here, we tackle all valve-related issues, ensuring your systems run as smoothly and efficiently as possible.

Custom Pipe Fabrication

We specialise in the design and construction of bespoke pipe systems.

Our team works closely with each individual client, carefully crafting pipe solutions tailored to their unique specifications. This attention to detail ensures a personalised service and high-quality results for every project.

Industrial Pipe Installation

Our team at Anderson Engineering And Welding Services are experts at installing a wide range of industrial pipes.

We draw upon our expertise to ensure each installation is carried out precisely, providing reliability and longevity in our work. Contact us today for industrial pipe installation.

Pipe Welding & Joining

Our team boasts of expertise in both joining and welding pipes of diverse materials. We take pride in our work, ensuring high-quality results with attention to detail.

With years of experience behind us, we provide professional, reliable and durable solutions for all your pipe-related needs.

On-Site Pipe Maintenance

We take pride in providing highly dependable on-site pipe repair services. Our team of skilled professionals use industry-approved practices, ensuring every job is done to the highest of standards.

Never stress about pipe damage again, simply contact us today for a fast and efficient pipe repair service.

Piping Design & Engineering

We specialise in providing unique pipe designs and have the capability to undertake and successfully execute complex engineering projects.

Our dedicated team utilise their exceptional skills and industry knowledge to deliver high-quality outcomes that exceed our clients' expectations

A Range of Materials & Configurations for Piping

Our range offers a diverse choice of materials and configurations to meet any specific piping requirement, including various alloys, plastics, and metals, each uniquely purposed for different applications and environments.

Whether your project requires durability, temperature resistance, or chemical compatibility, our team is able to advise on the optimal solution to fit your needs. Trust Anderson Engineering And Welding Services for high-quality piping installations every time.

Industrial Pipe Fitting for HVAC Systems

Anderson Engineering And Welding Services offers reliable and high-performance industrial pipe fitting services specifically designed for HVAC systems. Ensuring the smooth and efficient operation of an HVAC system is incredibly crucial to any industry. It is central for maintaining a comfortable environment and optimising productivity, and this is where Anderson Engineering And Welding Services steps in. Our team take immense pride in their ability to fit HVAC pipes effectively and accurately.

We ensure that each piping system we work on meets and often exceeds industry standards. Our services are executed with precision and attention to detail, allowing your HVAC system to function optimally at all times, reducing downtime and enhancing business efficiency. With our expertise and commitment, you can place your HVAC system worries aside and focus on your core business.

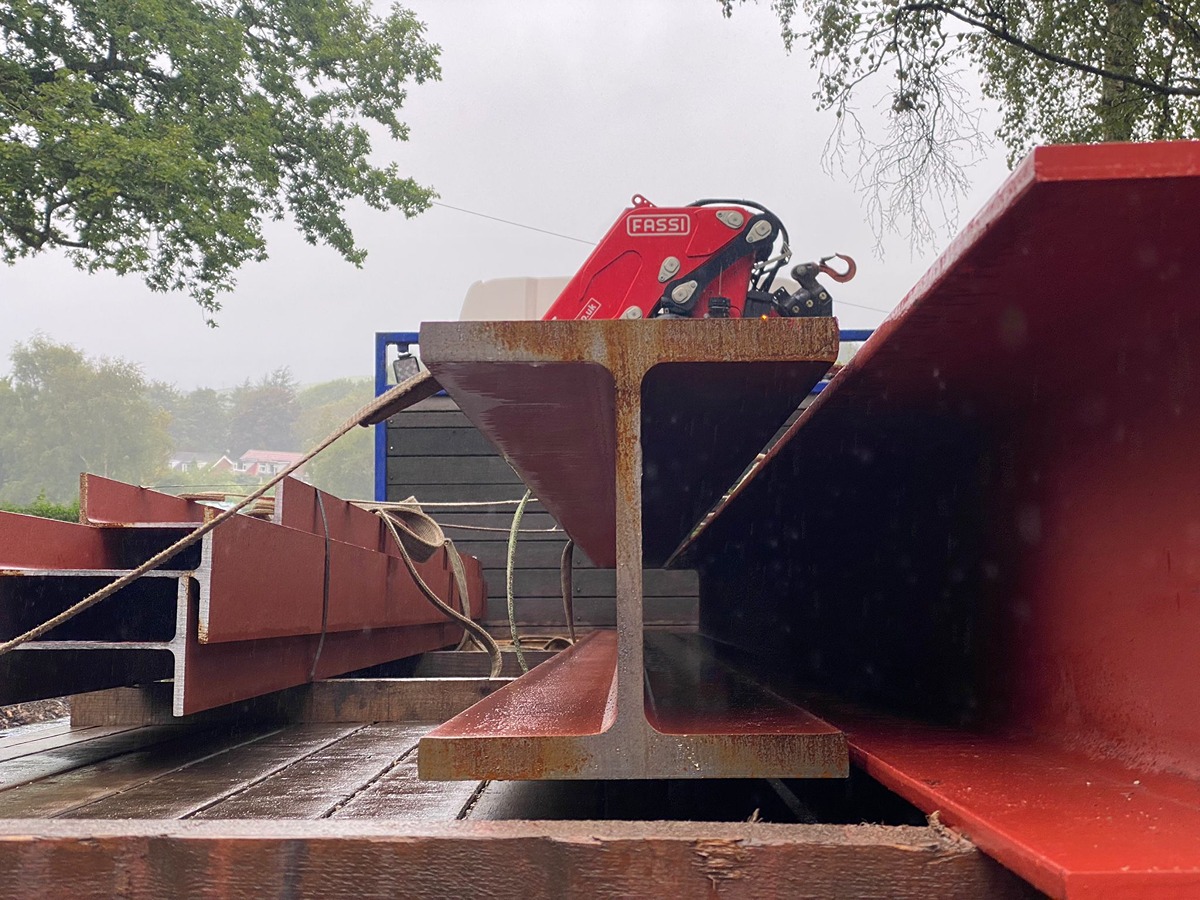

Structural Steel Suppliers Manchester

Are you looking for structural steel supply and installation services? Your search ends here with Anderson Engineering And Welding Services. We offer top-tier engineering services, ensuring your projects are completed with utmost precision and quality.

Mobile Welding Services Manchester

At Anderson Engineering And Welding Services, our engineers provide a high-quality mobile welding service. They guarantee flawless work on each project, ensuring that your expectations are always met, if not exceeded, every single time.

Bespoke Fabrication Services Manchester

With Anderson Engineering And Welding Services, you can transform your ideas into reality. Our customised fabrication services are tailored to meet your unique requirements with precision and finesse.

Frequently asked questions about Industrial Pipe Fitting

Industrial pipe fitting is the process of connecting and managing pipes used in factories, plants, and other industrial sites. These pipes carry important materials such as water, gas, oil, chemicals, and steam. Fittings are used to join pipes together, change direction, adjust flow, or seal the ends of pipes. Proper pipe fitting ensures that these systems work safely and efficiently under pressure or in extreme conditions.

The materials used in industrial pipe fitting depend on the type of system and what the pipes carry. Common materials include carbon steel, which is strong and handles high pressure well. Stainless steel is used when the pipes need to resist rust or carry chemicals. Copper is often chosen for systems involving heat or water.

PVC, which is a type of plastic, is lightweight and handles many chemicals. Brass is also used because it is durable and resists corrosion. The right material helps prevent damage and keeps the system working for longer.

There are several different types of pipe fittings, each with a specific job. Elbows are used when the pipe needs to turn in a different direction. Tees allow the pipe to split or join with another pipe. Reducers are used to connect pipes of different sizes. Couplings join two pipes in a straight line, and unions do the same but can also be taken apart easily.

Caps and plugs are used to close off the end of a pipe. Valves are used to control the flow of the material inside the pipe. These fittings make it possible to build complex pipe systems that work safely and correctly.

To choose the correct fitting, it is important to think about several things. The material of the fitting should match the type of pipe and the material it carries.

The size and shape of the fitting must be right to make a secure connection. It is also important to check the temperature and pressure the system will handle, as not all fittings are made for the same conditions. You should also decide how the fitting will connect to the pipe, such as by threads, welding, or flanges. Finally, the fitting should meet industry standards to make sure it is safe and reliable.

Threaded fittings are screwed onto the pipe. They are quicker and easier to install, and they can also be removed if needed. However, they may not be as strong and can sometimes leak if they are not sealed properly.

Welded fittings are joined by melting the metal and creating a permanent seal. These are stronger and better for high-pressure or dangerous systems. However, they need more time and skill to install, and they cannot be taken apart easily.

The way a fitting is installed depends on the type of connection it uses. Threaded fittings are screwed on by hand or with tools, and a sealant like tape or paste is used to stop leaks. Welded fittings need heat and are joined using special welding tools. Flanged fittings are joined with bolts and gaskets, which help seal the gap between the two pipe ends.

Other types, like push-fit or compression fittings, are simply pressed together. Each type of fitting must be installed carefully to make sure the system is safe and leak-free.

Some of the most common problems with industrial pipe fittings include leaks, cracks, and blockages. Leaks can happen if the fitting is not sealed properly or if it has become worn out. Cracks may form due to high pressure or extreme temperatures. Blockages can be caused by dirt, rust, or other build-up inside the pipe.

In some cases, the fitting might not line up properly with the pipe, which can put stress on the system. These problems can lead to breakdowns, so they need to be found and fixed quickly.

Maintaining pipe fittings is important to keep the whole system working properly. This includes regular checks for leaks, rust, or cracks. Any loose fittings should be tightened, and the inside of the pipes should be kept clean. Valves and other moving parts may need to be greased to keep them working smoothly. If any seals or gaskets look worn out, they should be replaced.

Keeping a regular maintenance schedule can help prevent bigger problems and make the system last longer.

Pipe fittings should be replaced when they are damaged, worn out, or no longer working as they should. Signs that a fitting needs replacing include visible cracks, leaks, rust, or poor sealing.

Fittings may also need to be replaced if the system has been changed or upgraded, such as when the pressure is increased or a different substance is used in the pipes. Replacing fittings at the right time helps avoid breakdowns, saves money, and keeps the system safe.

Using the correct pipe fittings is vital in any industrial system. They help control the flow of materials, prevent leaks, and protect the people working near the system.

A proper fitting also helps keep pressure stable and ensures that the system works as planned. Poor-quality or incorrect fittings can cause leaks, damage, or even accidents. This is why every fitting must be chosen, installed, and maintained carefully, to keep the whole system safe, reliable, and efficient.