Hydrostatic testing is a safety process used to check the strength and leak-tightness of many types of equipment. It uses water to test for leaks or weak points. The pressure applied during the process helps reveal any damage or flaws in the item being tested.

Discover common items that require hydrostatic testing, including pipelines, boilers, and pressure vessels. Learn why this process is essential for safety and leak prevention.

Pipelines and Water Mains

Pipelines and water mains are vital for delivering clean water to homes, schools, hospitals, and businesses. These systems carry large volumes of water under pressure, and even a small leak can lead to serious problems such as flooding, contamination, or damage to buildings and roads.

A hydrostatic test is used to check if the system is strong and secure. During the test, the pipeline is filled with water and pressurised to a level higher than normal operation. If the pressure drops or leaks appear during this process, the pipeline may need repair or full replacement.

Many companies offer hydrostatic testing services for new pipe installations or to check older systems for signs of wear. Regular testing helps prevent costly damage and keeps water supply systems running safely.

Fire Extinguishers and Cylinders

Fire extinguishers and gas cylinders are used in homes, schools, offices, factories, and other public spaces. They hold pressurised contents that could be dangerous if the cylinder is damaged or faulty.

Over time, metal can weaken or corrode, making the cylinder more likely to fail. A hydrostatic test checks for any leaks or weaknesses that could cause it to burst or not work when needed.

Many companies offer hydrostatic testing as part of routine fire safety checks. This service helps keep fire safety equipment ready to use in case of emergency.

Gas and Oil Pressure Vessels

Pressure vessels used in gas and oil industries need to be checked regularly. These containers hold gases or liquids under high pressure, and a failure could lead to fire, explosion, or serious harm to people and the environment.

Hydrostatic testing helps ensure that each vessel is strong enough to do its work safely and without risk. Water is added to the vessel, and it is then pressurised to test for leaks, cracks, or other weaknesses.

This test is often required by law, especially before the vessel is used again after being in storage or after repair. Companies offering this service help meet safety rules and reduce the risk of equipment failure.

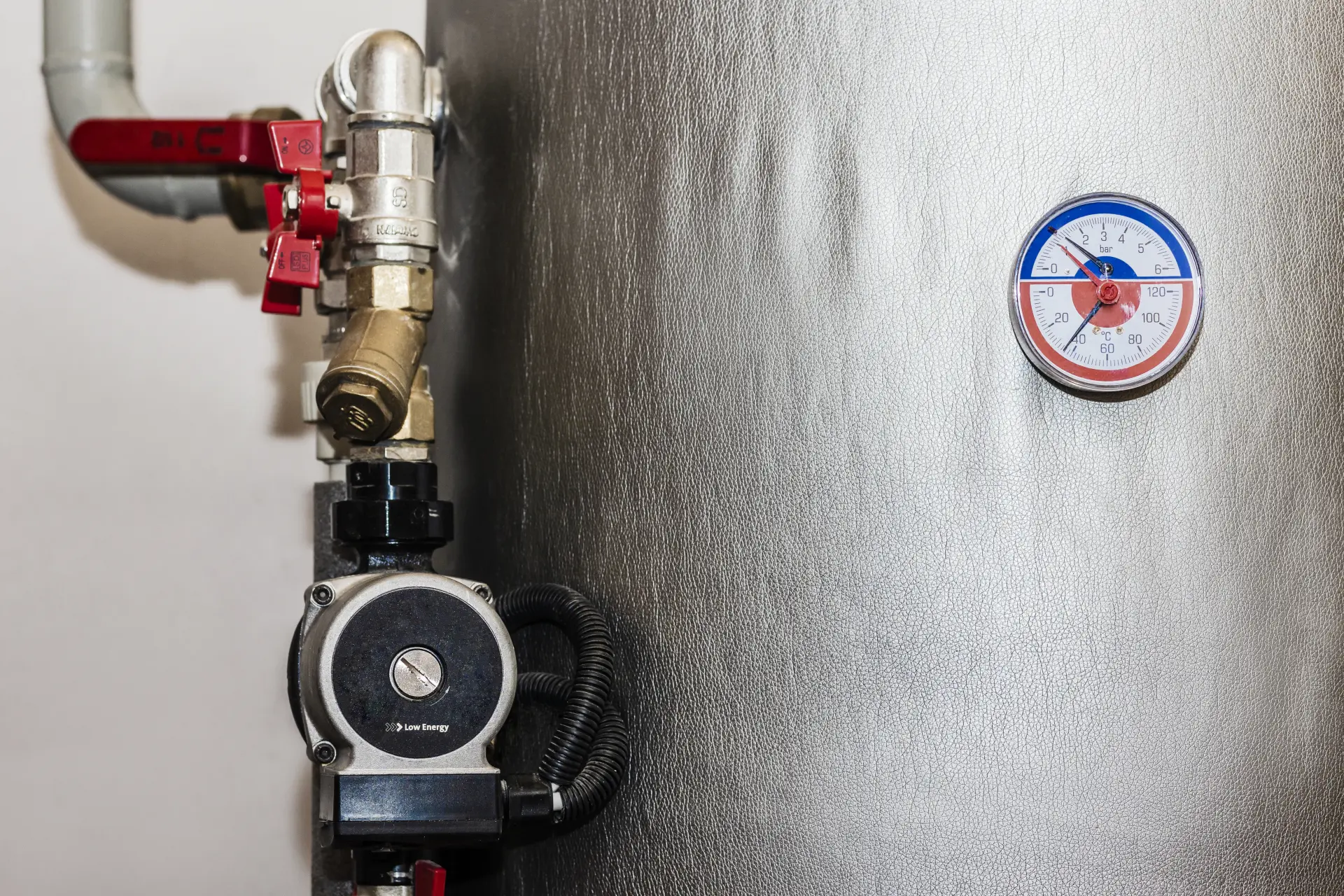

Boilers and Heating Systems

Boilers and heating systems are common in homes and commercial buildings across the country. Because they hold water and steam under high pressure, they must be checked to make sure they are safe to use.

A hydrostatic test is often done when a new boiler is installed, after a major repair, or as part of regular checks. This process helps find any leak or fault that may cause the system to fail.

The test gives building owners and users confidence that the system will work well and not cause damage or injury.

Storage Tanks and Containers

Storage tanks may hold anything from drinking water to chemicals or fuel. These tanks need to be sealed tightly to prevent leaks, spills, or contamination of the surrounding area.

Hydrostatic testing is used to check the strength and tightness of the tank. The process involves filling the tank with water and applying pressure to see if it holds without leaking.

If the tank leaks or loses pressure, it fails the test and must be repaired before being used. This kind of testing is helpful for tanks that are being installed for the first time or ones that have been out of use.

Many companies offer tank testing services to help meet safety standards and ensure the container is ready for work.

Hydrostatic testing ensures the safety, reliability, and compliance of systems by detecting issues and protecting the environment across various industries. Anderson Engineering And Welding Services provides expert hydrostatic testing services across Manchester & North West that are guaranteed to keep your equipment in good condition.