Why Water Supply Systems Need Testing

Hydrostatic testing is essential for verifying the strength and integrity of water supply systems. Hydrostatic testing works by filling pipes or tanks with water and pressurising them beyond their normal operating levels to detect leaks and structural weaknesses before the system goes into service.

Hydrostatic testing protects the public's health by checking that drinking water doesn't contain pathogens or other harmful chemicals. Hydrostatic testing involves microbiological sampling for E. coli, chlorine residuals, and checking the water's pH to confirm that the system is working and the water remains safe to use and consume. Pressure and flow tests can also reveal whether the system's pumps, valves, and hydrants can meet everyday demands and high-pressure usages.

How Hydrostatic Testing Works

Hydrostatic testing is a critical process that verifies the safety, strength, and tightness of water supply systems before they are commissioned or after major repairs. Hydrostatic testing is widely used on new mains, storage tanks, and other pressurised components to ensure these systems are compliant with British Standards such as BS EN 805 and the Water Industry Specifications (WIS).

The process begins with isolating sections of the pipeline or vessel that are going to be tested. All the open ends are securely sealed with end caps or flanges, and suitable air vents are fitted to release trapped air. The system is then slowly filled with clean water to avoid introducing contaminants, and any air pockets are expelled since trapped air can give misleading pressure readings and compromise your safety.

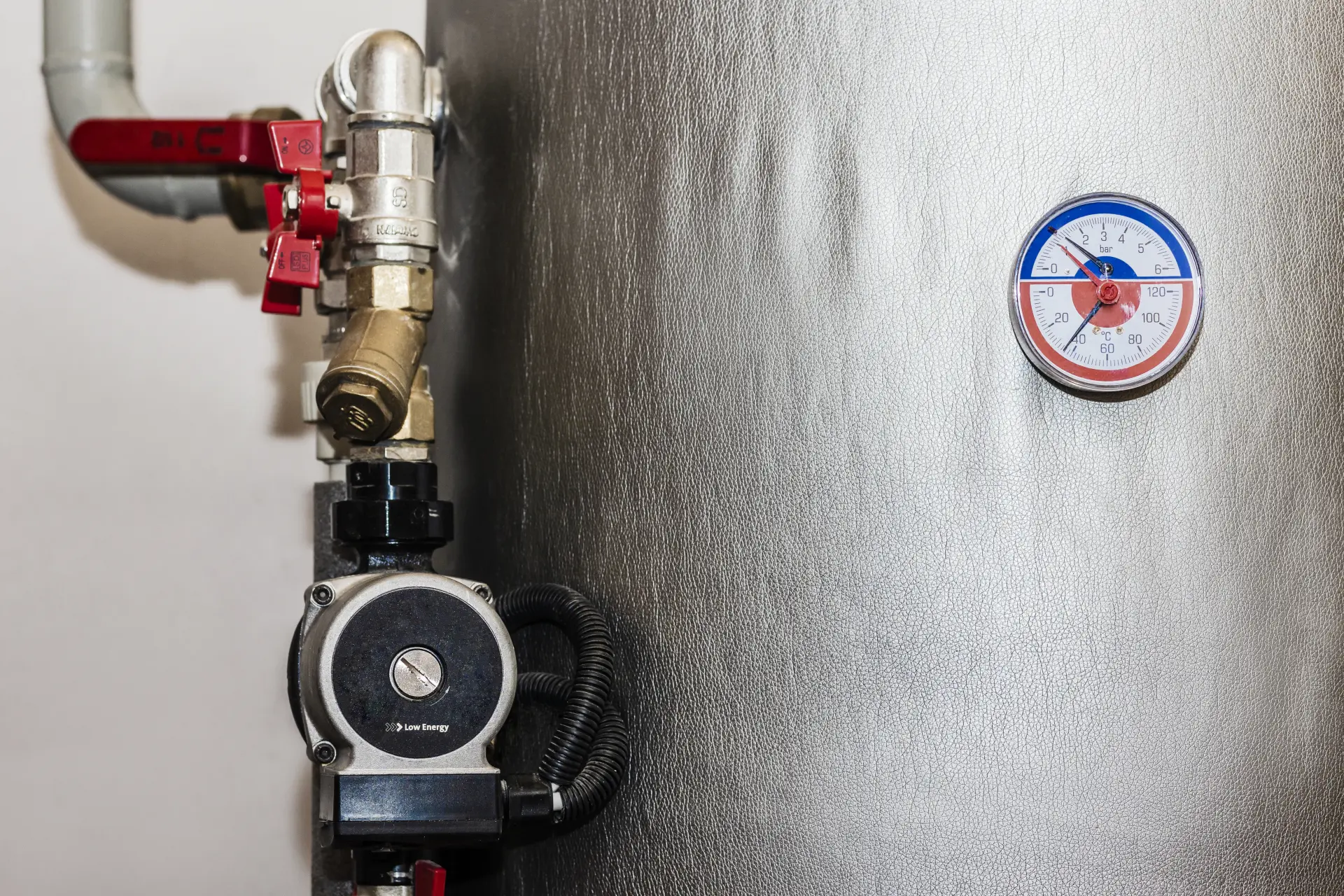

Once the system is filled, the pipeline is pressurised using a calibrated pump to roughly 1.5 times the operating pressure. This pressure is then held for typically one to two hours while engineers monitor the gauges for any drops in pressure. If pressure loss is found, the team will investigate the tank for visible leaks and loose joints.

Hydrostatic testing prevents system failures and reassures regulators, insurers, and end users that their water supply systems are safe, clean and hygienic. By simulating real-life pressure conditions in a controlled environment, hydrostatic testing ensures the system is safe, durable, and fit to deliver clean, reliable water.

Detecting Leaks and Weak Points

Hydrostatic testing protects water supply systems by revealing hidden leaks and structural weak points before they can escalate and compromise the entire system. By pressurising pipes and tanks with clean water under controlled conditions, engineers can ensure that water supply systems perform safely at or above their intended operating pressures.

The engineers will isolate a pipeline section and purge the air to prevent false readings. They'll then fill the test piece with clean water and raise the pressure using a calibrated pump. After the system has stabilised, the operators will track the pressure readings and check for visible leaks. Hydrostatic testing exposes defects that routine maintenance might miss, such as poor joint assembly, cracked fittings, pinholes, flawed welds, and damage from transportation. This test can also flag up any weaknesses caused by insufficient thrust restraint or unanchored bends.

Preventing Water Contamination

Hydrostatic testing ensures that pipelines, tanks, and other components of water supply systems are completely sealed before they are put into service. Even a small leak or structural defect can allow external contaminants like soil, bacteria, chemicals, or wastewater to enter the system, especially when the internal pressure drops during repairs, pump shutdowns, or demand surges. By thoroughly checking for leaks under controlled conditions, hydrostatic testing eliminates these potential risks before water ever reaches consumers.

If a drop in pressure occurs, it tells engineers and operators that there's a possible leak. The hidden leak will then be found, repaired, and the system will be thoroughly inspected to ensure it can hold pressure consistently. Passing a hydrostatic test demonstrates that the system is watertight, structurally sound, and incapable of allowing contaminated groundwater or pollutants to infiltrate the system during operation.

UK standards such as BS EN 805 demand that water supply systems are thoroughly tested and documented before any water mains are commissioned. These records assure regulators, utilities, and the public that their drinking water is safe and protected. Additionally, the system is typically flushed and chlorinated after a hydrostatic test to remove any residual microbes before it's put to use.

At Anderson Engineering And Welding Services, we deliver certified hydrostatic testing services for water mains, pipelines, and tanks. Our engineers can isolate, pressurise, and inspect water systems to detect hidden leaks and structural weaknesses. We provide detailed reports and ensure your water is safe, clean and hygienic to use.