The Importance of Testing Firefighting Equipment

Firefighting equipment must work flawlessly the first time, every time. Hydrostatic testing verifies the integrity of hoses, nozzles, hydrants, portable fire extinguishers, and breathing-air (SCBA) cylinders. By proving that these components can safely withstand high amounts of pressure, hydrostatic testing helps prevent catastrophic failures during real-life incidents, when people are at risk.

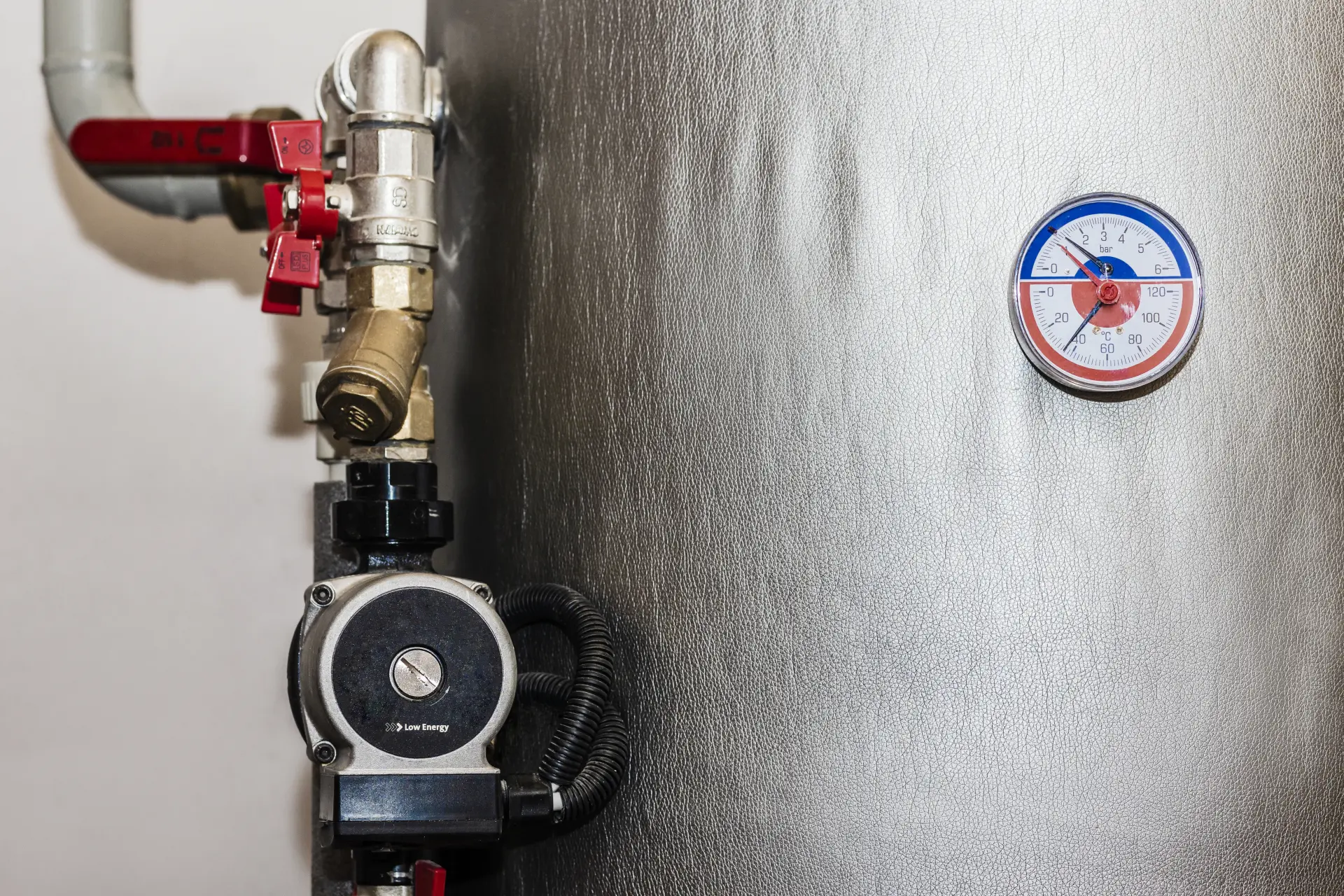

In a hydrostatic test, a component is filled completely with water, purged of air, and pressurised using calibrated equipment to a specified level and duration. Technicians will then monitor the component for pressure loss, deformation, seepage, or signs of damage. For appliances like sprinkler and standpipe systems, hydrostatic testing verifies that the pipe joints, valves, and fittings are tightly sealed and comply with regulations.

The test can also uncover issues such as hose delamination, blistering liners, cracked valve bodies, corrosion, pin-holes and micro-cracks in cylinders. Hydrostatic testing ensures that firefighting equipment can handle large surge pressures from pumps without failing.

Types of Firefighting Equipment That Require Testing

Hydrostatic testing verifies the safety and reliability of fire equipment and confirms that pressure-retaining components are leak-tight and structurally sound before they are used. A wide range of firefighting equipment needs to be hydrotested in compliance with the requirements set by British Standards and manufacturer instructions.

Water, foam and powder units, like portable fire extinguishers, have pressure vessels that need to be periodically tested, while high-pressure CO2 extinguishers and cartridges need to be tested by approved cylinder specialists. If these components pass their hydrostatic tests, it ensures the shells, neck threads, and valves can all withstand high-pressure usage without the risk of rupturing.

Lay flat firefighting hoses and their couplings also need to be hydrostatically tested to check that the liners, jacket adhesion, and end fittings are securely fixed in place. Fixed hose reels are also pressure tested to verify the integrity of the swivels and valves, which helps to prevent splits or leaks during prolonged flows.

Building fire mains, such as dry risers and wet risers, need to be tested at defined intervals. Hydrostatic testing ensures the jointing, landing valves, non-return valves, and anchors can safely deliver high flows of water over multiple storeys. Private fire hydrants and underground pipework also need to be pressurised to confirm the chambers are structurally sound.

Safety Benefits of Regular Testing

Regular hydrostatic testing is crucial for preventing catastrophes. Hoses, couplings, nozzles, standpipes, hydrants, extinguishers, and SCBA cylinders are all filled with water and pressurised to a specified level for a set time, and any drops in pressure, seepage, coupling movement, or thread distortion can become a massive problem. Removing or repairing these components before they're used on the frontline can prevent hoses from bursting, cylinders from rupturing or valves from splitting during an emergency.

Periodic hydrostatic tests of SCBA and other high-pressure cylinders help confirm the integrity and performance of the shells and valves, which helps lower the risk of violent bursts or failures during transportation or operation. Documented pass/fail outcomes can also guide the integrity of steel components before metal fatigue becomes a hazard.

How Hydrostatic Testing Works

The hydrostatic testing process for firefighting equipment varies slightly depending on the type of equipment being tested. First, the equipment is visually inspected for signs of damage, corrosion or contamination and any defective components are repaired or removed before the testing begins. The component is then completely filled with clean water from an approved source. This step is essential because water, unlike compressed air or gas, stores minimal energy, which reduces the risk of failures or bursts during pressurisation.

Air is then carefully expelled from the system using a calibrated pump to prevent false readings and unsafe conditions. The pressure is then gradually raised to meet the specified test level, before being held for a set period of time, often ranging from several minutes for hoses to 30 minutes or longer for pipework and fixed installations. During this hold time, technicians will monitor the gauges for pressure drops and inspect for leaks, bulging, joint movement or deformation.

Upon completion, the results are recorded, noting the pressures applied, time durations, serial numbers and calibration details. These records provide traceable proof that the test is compliant with UK standards such as BS EN 671 for hose systems, BS EN 694 for fire hoses, BS EN 12245 for SCBA cylinders, and BS 9990 for non-automatic firefighting systems.

At Anderson Engineering And Welding Services, we deliver certified hydrostatic testing services for water mains, pipelines, and tanks. Our engineers can isolate, pressurise, and inspect water systems to detect hidden leaks and structural weaknesses. We provide detailed reports and ensure your water is safe, clean and hygienic to use.